CO₂ Recovery

CO₂ recovery units from CO2 Lab

provide a reliable solution for capturing and reusing carbon dioxide, catering to various food and chemical industries. These units operate within a capacity range of 500 kg CO₂/h to 5,000 kg CO₂/h

Applicable to multiple emission sources, including:

- Bioethanol production

- Breweries

- Biogas plants

- Cogeneration units

- Chemical industries (e.g., ammonia plants)

Enhance Efficiency with CO₂ Recovery Solutions

With CO2 Lab's recovery units, businesses can secure a sustainable supply of CO₂ while optimizing operational efficiency. We offer customized solutions tailored to each enterprise's specific needs. Our experts design, manufacture, and install equipment that fits even in space-constrained environments.

Our CO₂ recovery systems enable:

- Capturing exhaust CO₂

- Purification, liquefaction, and storage

- Delivery of liquefied CO₂ as per operational demands

The final output is liquid CO₂ of food-grade purity, meeting DSTU 4817:2007 standards for food applications and, if required, complying with the European ISBT standard.

CO₂ self-recovery is not just a cost-saving strategy but also a responsible step toward sustainability.

Advantages

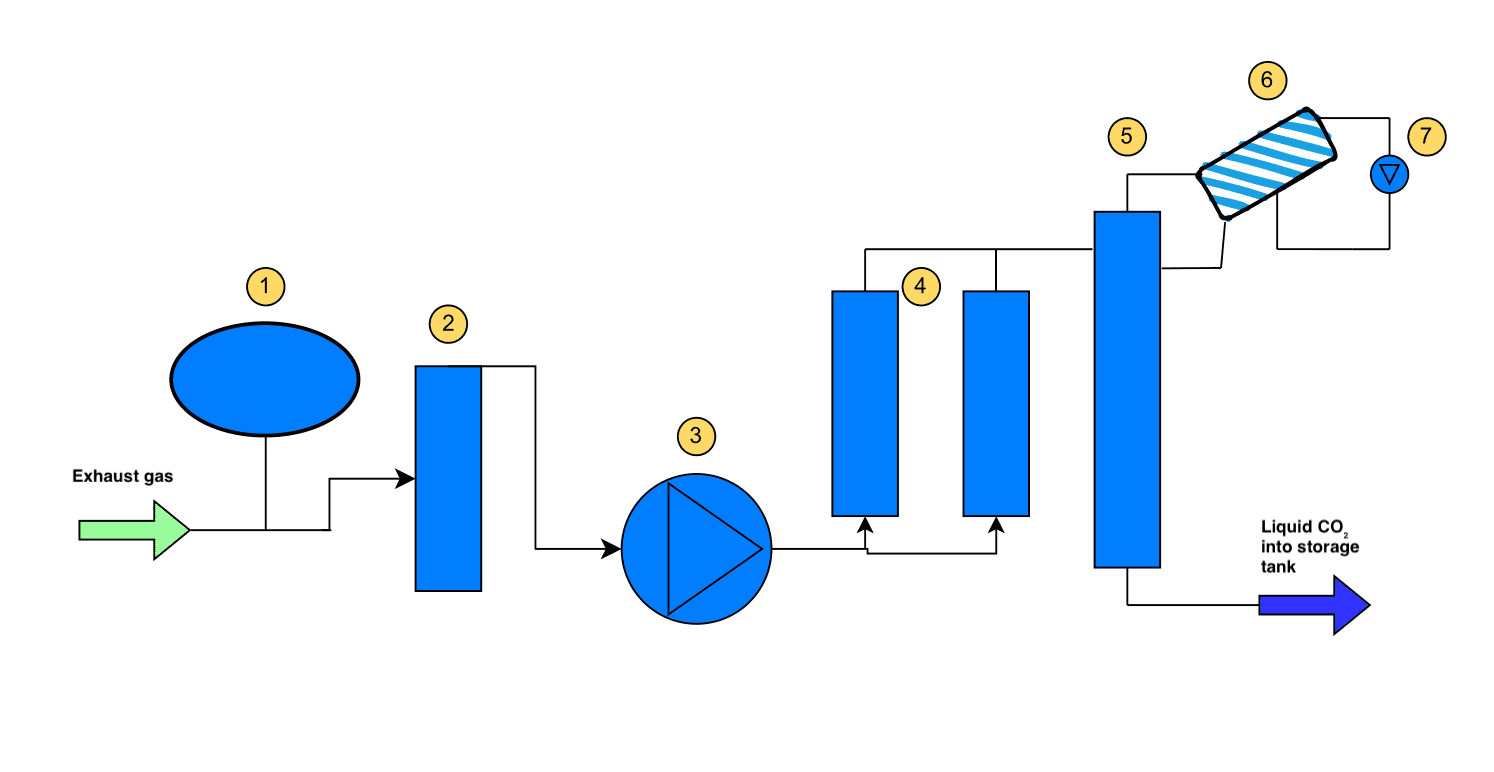

CO₂ Recovery Process

1. Gas ballon: captures and directs exhaust gas into the recovery system

2. Raw Gas Purification Column: removes water-soluble contaminants (e.g., ethanol) via a gas scrubber

3. Compressor: increases gas pressure to 18 bar while eliminating condensates

4. Filtration & Drying Unit: a two-stage activated carbon filter removes residual impurities and moisture; automatic filter regeneration is carried out using heating elements and dry CO₂ gas

5. Reboiler: eliminates remaining O₂

6. CO₂ Condenser with Refrigerant: liquefies CO₂ through a refrigerant-cooled condenser

7. Refrigerant Compressor: supports the condensation process